Anthon GmBH

International Woodworking Fair Trade Show

Trade Show Booth Case Study

Our Process

Problem

The two-month timeline was the biggest challenge in preparing for the IWF trade show. We had two months to complete the project and less than two weeks to finalize the design. This included printing walls, setting up test runs, and buying furniture and materials that could be shipped within our timeframe. We also had to get the blueprint approved by IWF before we began building the booth. There were some unexpected issues, including receiving damaged equipment, delayed deliveries, and functionality requests, which all added pressure to the project, but ultimately, our dedicated team delivered. /p>

Objective

- Capture leads and stand out with an eye-catching booth.

- Create a vibrant, open, and inviting space to encourage easy movement and accessibility.

- Engage visitors through TV displays and collateral brochures.

Strategy

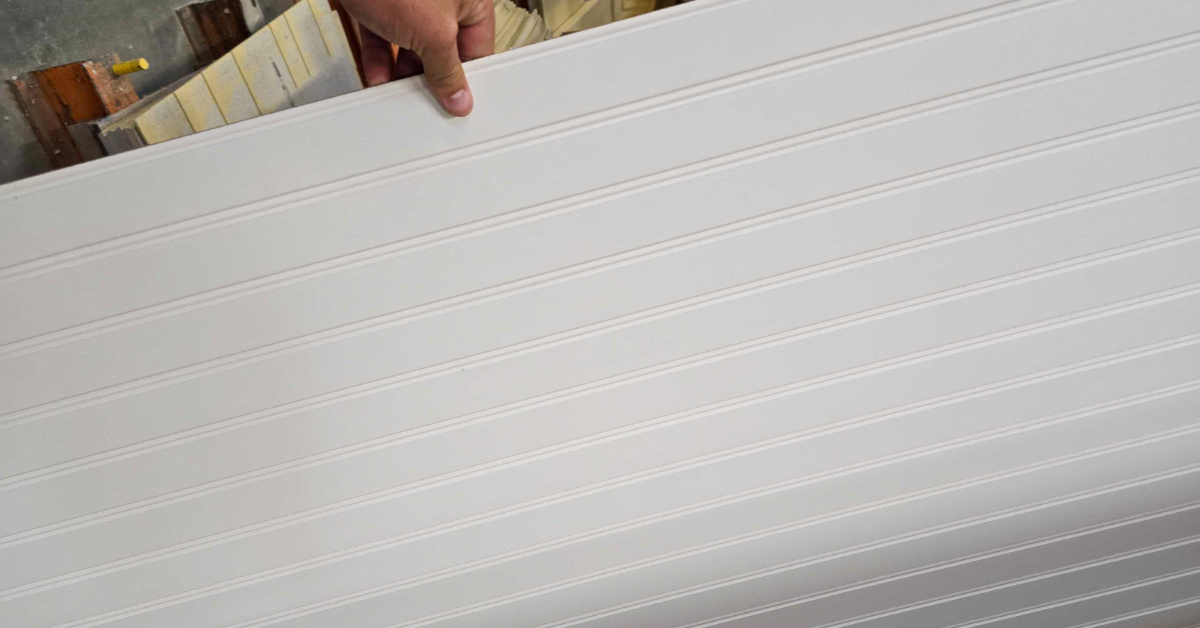

The primary strategy for designing the trade show booth focused on meeting Anthon’s needs and exceeding expectations within a two-month timeline. This involved quickly sourcing materials, maintaining the booth’s unique look, and creating a standout trade show experience. Unlike many competitors, who used dark colors, we designed the booth to reflect the Anthon brand through vibrant white colors and light wood accents rather than red or black. During preparation, adjustments were made to meet IWF’s height requirements and effectively utilize the available space.

Working with Anthon, a large international company, required us to act swiftly and thoroughly. This included hand-delivering the booth and providing extensive on-site support. We also managed to freight the materials to IWF, build the trade show booth on-site, and organize the breakdown after the show. During the show, we provided hands-on support to ensure the Anthon representatives could work at top performance by delivering coffee, lunch, and any other needs; for example, we delivered new furniture mid-convention to allow for more storage within the booth.

Results

Anthon gained significant brand exposure at the IWF trade show and successfully collected numerous leads for their turn-key solutions and panel processing lines. A lead capture system was used where attendee badges were scanned to track contact information and measure conversions. Anthon was extremely pleased with the booth and asked to take all the fabric and materials with them to replicate the setup for trade shows in Germany. After obtaining approval from IWF to dismantle the booth, we accommodated their team by quickly dismantling the requested fabrics and materials. The success of the tradeshow has solidified our ongoing relationship with Anthon, and we will continue to assist in sourcing materials for their future events.

Trade Show Booth Design and Build

Anthon’s trade show booth featured key design elements for both function and appeal. Vibrant white walls backed with noise-reducing materials created the booth’s unique look and feel. This soundproofing created a quieter, more tranquil space and allowed Anthon’s team to have meaningful conversations with visitors. A large TV displayed a video of Anthon’s processing line and introduction. During the build, we made adjustments to enhance the booth. When the TV was too small, we quickly acquired a larger one and installed it during one of the nights between the show’s open hours. Our team also built a custom wood backing onsite to accommodate the new TV better. These adjustments made the booth visually striking and highly functional, exceeding Anthon’s expectations.

On-Site Support

We provided extensive on-site support, including delivery and breakdown of materials and concierge services. A maintenance team was available all three days to handle any issues that could have arisen. We were ready to print and supply additional collateral if needed. When Anthon requested more storage, we quickly purchased and delivered an ottoman that matched the booth’s look. This prompt support greatly improved Anthon’s team experience, allowing them to focus on their work and contribute to the brand’s success at the tradeshow.

Delivery, Set-Up, and Breakdown

The delivery was carefully managed and set up to make sure all materials were on time. First, our team did a test run to estimate the build time. Delivery was challenging as we needed to coordinate freight and move through the marshaling yard. Our team made sure to record and assign responsibility for all equipment. The biggest challenge during the breakdown was planning around the marshaling yard, which took an additional seven hours of our team’s time. We then planned time to pack everything up and keep all the items intact for Anthon. Our efficient handling had the booth ready as soon as Anthon arrived and made sure the fabric was packed and approved by IWF for their departure.